Portfolio

Read more »

Finished project

Read more »

Finished project

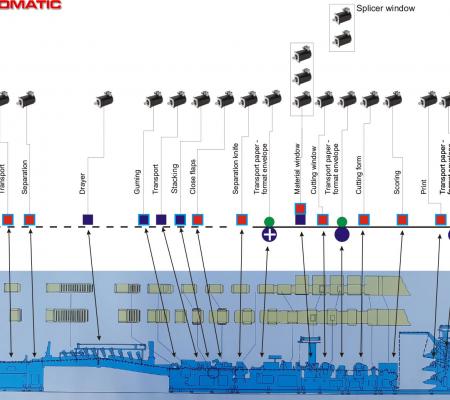

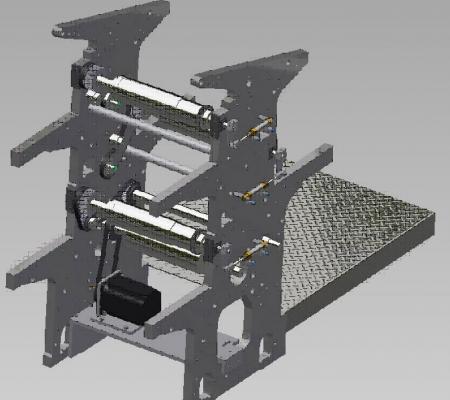

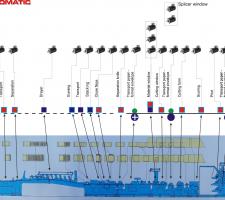

To improve the quality of your envelopes we will change the position of the Cross Scoring section, and provide the Cross Scoring section with the latest Mitsubishi servo technology and synchronize the encoder to the knife format.

The original Cross Scoring section of the 249 is placed between the separating cutting section and the bottom flap folding section causing paper jam, crash ups and imprecise score.

The original Cross Scoring section does not allow the machine adjusters to easily set the scoring shaft pressures to give a good quality product at higher speeds.

To avoid those problems the Technomatic Cross Scoring unit is placed between the printing section and the form cutting section of the W+D 249 and synchronised with the format knife. The Technomatic Cross Scoring unit will significantly improve the quality of your products and will reduce quality variations to achieve your customer quality specifications.

Ask about this service

Read more »

Finished project

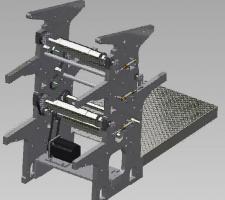

Our upgrade kit consists of the following equipment:

4 Servos, 1 per print section and 2 servos for web tension.

- 4 Servomotors and 4 inverters (1 for each Print Section).

- 1 Servomotor and inverter before printing for web tension control

- 1 Servomotor and inverter after printing for web tension control

- Complete electrical wiring

- PLC for in- and output control & motion control

- Camera for print quality control

- Encoder for synchronization with W+D 102

- Touchscreen panel for parameter control

- Software development and programming

- EWON internet connection module

Ask about this service

Read more »

Finished project

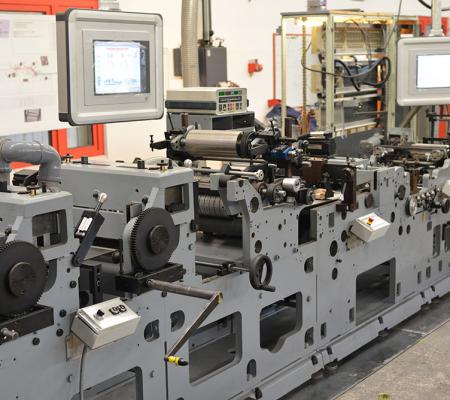

Dismantling of the complete machine

Cleaning, sandblasting frame, modules and painting

Repainting of the Frame

Replace - recondition all gears and cylinders

Replace all bearings (SKF)

Replace all rubber rolls / cylinders

Reassemble machine

Ask about this service

Read more »

Finished project

Fully Servo-Technology controlled envelope machine upgraded by Technomatic.

Download our Information Brochure

Ask about this service

Read more »

Finished project

Upgrade package for your Stork Contiweb splicer to eliminate the existing electronic problems and the difficulty to find spare parts. Resulting in a gain of production efficiency and reliability.

- Change and reinstall the paper roll drive and web tension drive with 2 Mitsubishi servo-motors.

- Install the respective controllers and regulators.

- Install new HMI - PLC and touchscreen control panel.

- Complete rewiring of the cabinet.

- Change all electronic components.

- Replace the pneumatic system with a new pneumatic Valve Terminal.

- Provide a Wireless modem for Technomatic technical support.

Ask about this service

Videos

Videos +33 674 647 902

+33 674 647 902

arnaud.coste@technomatic.pl

arnaud.coste@technomatic.pl