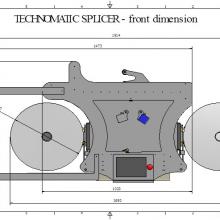

Technomatic Window Splicer

In addition to our envelope production systems we also offer systems for unwinding and splicing of window material and silicone paper. The splicing is done during the production process. This guarantees highest productivity and efficiency.

Features:

- Designed to feed a continuous supply of window material into the process line.

- The window splicer can be installed in-line above, or next to the envelope production machine.

- Driven by two servomotors for precise continuous unwinding and splicing.

- Works well with pressure sensitive label stock, many films and various papers and laminates.

Specifications:

- Real Diameter: max. 500 mm

- Reel width: min. 30 mm

max. 330 mm

- Reel weight: max. 70 kg

- Reel Quality: The material reel must be wound tight and right-angled

Allowable variation of concentricity = 2 mm

Allowable variation of run-out =2 mm

- Changing speed: 200 m/min, 3.3 m/s

- Core diameter: 70-77 mm

- Core material: Cardboard, Minimum wall thickness = 8 mm

- Splice connection: Standard: 30 mm overlapping with adhesive tape

- Adhesive tape with: 25 mm

Installation is not included depends if the splicer is installed above the machine or next the envelope machine.

Ask about this service

Videos

Videos +33 674 647 902

+33 674 647 902

arnaud.coste@technomatic.pl

arnaud.coste@technomatic.pl